Description : - The new generation of static induction furnaces can be divided into two ranges: ST and ST Plus The ST serie has a simple digital thermostat that allows you to set the melting temperature of the metal and to see the real one. The ST Plus serie has a touch screen panel that allows the user to select various parameters, including different methods of reading temperatures: standard "K" thermocouple at the bottom of the crucible, thermocouple external "S " or "K", or optical pyrometer. These can be applied as an option. The newest generation circuit has a power and control board with SMD technology, which could achieve working cycles more profitable and faster than previous systems with worn crucibles. A novelty is the single-phase 230V power supply for the ST123 model that also has the peculiarity of being able to use crucibles of 1kg, 2kg and 3kg without intervening in any parameter of the oven. An interesting option is the casting chamber vacuum applied to the machine that allows you to do wax casting directly next to the furnace.

Tecnical Details | MOD | iD123 | iD04 | iD05 | iD10 | iD12 | iD18 |

Overall Dimension | mm | 470X510X920 | 520X 560 X970 | ||||

Weight | kg | 63 | 66 | 66 | 71 | 71 | 78 |

Crucible Au 750 | kg | 2,8 | 4,8 | 6,1 | 12 | 13,5 | 15 |

Capacity Ag 925 | 1,9 | 3,2 | 4,1 | 8,1 | 9,2 | 10,2 | |

Max Temparature | oc | 1150 (1600 Optional w ith Optica l Pyrometer) | |||||

Min. Water Flow | I/min | 4 | |||||

I Install Power | kW | 3,5 | 6 | 7 | 11 | 12 | 15 |

Power Supply | Vo lt | 230 3×400 3×230 | 3×400 3x 230 | 3 x400 | |||

POWER | kW | 3 | 5,5 | 6,5 | 10 | 11 | 14 |

FREQUENCY Start of machine operation to reach Set Temperature | kHz | 20 ±7,5% | 20 ±7,5% | 20 ±7,5% | 20 ±7,5% | 20 ±7,5% | 20 ±7,5% |

Radiate Power | w | < 5 | <5 | <5 | <5 | <5 | < 5 |

POWER | kW | 0,2 | 0,2 | 0,2 | 0,2 | 0,2 | 0,2 |

FREQUENCY> Maintaining Set Temperature | kHz | 32 ±7,5% | 32 ±7,5% | 32 ±7,5% | 32 ±7,5% | 32 ±7,5% | 32 ±7,5% |

Radiate Power | w | < 5 | < 5 | <5 | < 5 | < 5 | < 5 |

Termocouple Position | Under Crucible | ||||||

Cruc ible type | With Fixed Ceramic Jacket | ||||||

Temperature Control | |||||||

Optional | External thermocoup le w ith support | ||||||

Optional | Optical Pyrometer w ith support ( 1600°C) | ||||||

Optional | Gas Burner | ||||||

Optional | Cylinder Microcasting Chamber Max Cylinder Dimension mm 0120x320h | ||||||

The static tilting furnaces consist of a swivel head which is mounted the heating inductor, connected to the induction of MF via two flexible cables, copper water-cooled. The medium frequency induction circuit with melting high speed is set within a frame built with solid aluminum enclosed by panels powder coated. The swivel head made up of panels Sindanio asbestos-free and aluminum plates mounted on a stable base, the rotation is on two points by a motor acting on a tree where they placed two pulleys. All controlled by a control panel with rollover and emergency.

SPECIFICATIONS | iD – 2 + T | iD- 5 + T | iD – 10 + T | iD – 20 + T | iD – 30 + T | iD – 50 + T |

Electrical Power supply | 440V Three Phase | 440V Three Phase | 440V Three Phase | 440V Three Phase | 440V Three Phase | 440V Three Phase |

Max. Furnace Power | 3kW | 10kW | 15kW | 20 KW | 25 KW | 35 KW |

Useful Capacity (Au) | 2 kg | 5 kg | 10 kg | 20 kg | 30 Kg | 50 Kg |

Operating Frequency of converter | <20 KHz | <20 KHz | <20 KHz | <20 KHz | <20 KHz | <20 KHz |

Max. Operating Temp. | 1200°C | 1200°C | 1200°C | 1200°C | 1200°C | 1200°C |

Dimension | Varies | Varies | Varies | Varies | Varies | Varies |

Weight | 100 kg | 140 Kg | 150 Kg | 180 Kg | 240 Kg | 400 Kg |

Specification of Product:

|

Features |

|

|

Brand name |

Delmer |

|

Color |

Black & grey |

|

Finish type |

Rectangular Shape with Bright Enamel finish |

|

Dimension |

250X250X400 mm (for all capacity) |

|

Body material |

MS & SS |

|

Weight |

8 Kg |

|

Country of origin |

India |

|

Materials that can be melted |

Gold, Silver, Brass, Al & Its alloy. |

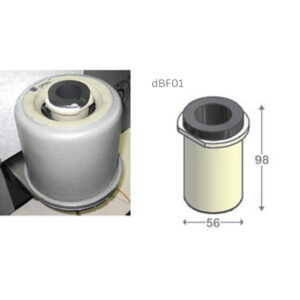

Bench Melting Furnace dBF01

Membrane Keyboard Digital Display

Membrane Keyboard Digital Display

Technical Details | Mod. | dBF01 |

Overall dimensions | mm | 500x480x585 |

Weight | kg | 50 |

Crucible capacity | kg | 1,54 kg Au 24kt |

Max Temperature | C | 1150 C |

Water Flow | Lt/min | 3 |

Installed Power | kW | 1,5 |

Power supply | v | 230V single phase |

Thermocouple position | Under crucible | |

Crucible type | With fixed ceramic jacket | |

Temperature control | Membrane Keyboard digital thermoregulator | |

A INDUCTION MELTING FURNACE IS WHAT?

An electrical furnace called an induction melting furnace heats a charge by inducing an electric current within it, without having direct contact with the induction coil.

An induction furnace is made up of water-cooled hollow copper tubes that can be assembled in various configurations depending on the application; the melting industry often uses copper coils that are cylindrical in shape. According to the Lenz law, a reversing magnetic field is produced when a high-frequency alternating current is fed through this copper coil. Any conductor (charge to be melted) placed in this magnetic field induces an internal circular current known as an Eddy Current. The primary coil and secondary coil are the two coils that make up an induction generator.

The primary coil absorbs current at high voltage, low ampere, and set frequency. The secondary coil changes this current into low voltage, high ampere, and high-frequency current, which is then supplied to the copper coil mentioned in the preceding sentence.