Consumables

Stainless Steel Needless

Their particular shape is used in magnetic Shiner machines only for the shining step, especially when there are internal surfaces impossible to reach by hand.

Stainless Steel Balls

The steel quality of the stainless steel balls is AISI 420/C norm guaranteed against oxidation, when used with MF products. To be used in the vibration and rotation machines with water and surface-active compounds only for Me shining step.

Stainless Steel Needless

Their particular shape is used in magnetic Shiner machines only for the shining step, especially when there are internal surfaces impossible to reach by hand.

Stainless Steel Needless

Their particular shape is used in magnetic Shiner machines only for the shining step, especially when there are internal surfaces impossible to reach by hand.

Stainless Steel Needless

Their particular shape is used in magnetic Shiner machines only for the shining step, especially when there are internal surfaces impossible to reach by hand.

Stainless Steel Needless

Their particular shape is used in magnetic Shiner machines only for the shining step, especially when there are internal surfaces impossible to reach by hand.

Investment Cleaner

Starjet MF 110

Designed for the world jewelry, the machine is used for the washing of trees form the plaster casting. Machine Is constructed entirely of steel AlS1304.

Circular Vibrator

This is a universal machine used for all the wet processes of finishing-Roughing, Sanding and Polishing on jewelry parts, all ferrous alloys especially stainless steel.

This is a universal machine used for all the wet processes of finishing-Roughing, Sanding and Polishing on jewelry parts, all ferrous alloys especially stainless steel.

The machine uses vibration effect that is transmitted to a polyurethane tank by an adjustable masses vibrator. Thus, the materials placed inside the tank gets three kinds of motion: centrifugal, helical and vibrant. Their combined action, together with water and abrasive materials (with Liquid compounds or paste) makes it possible to achieve superior levels of finishing.

Disc Finishing

Ideal for deburring of micro mechanical parts and for achieving a mirror finish.

Salient Feature

- Gap setting with rotation of the tumbler for a 0.035 mm setting.

- Maximum velocity of rotation 450 rpm which is the highest in the Industry.

- Complete polyurethane tumbler

- Long lasting steel ring instead of the conventional ceramic.

- Feather touch keyboard for fast data entry.

LCD-Panel

- LCD display for better visualization.

- Memory capacity for 25 processing programs.

- Date & Time display.

- It shows the barrel no. and also highlights the barrel which is in the process.

- Displays required processing time for each Barrel along with Running Tim..

- Through Menu, the PROCESSING TIME, FORWARD ROTATION TIME, REVERSE ROTATION TIME & SLOW END TIME can be set as per requirement.

- With SLOW END TIME the Machine runs at Slow speed in last processing time period, to achieve fine polishing.

- The container usage time can also be displayed.

- Memory capacity for 25 processing programs.

- Prominently displays the barrel number and the barrel in process.

- Displays processing time and running time.

Sand Blasting Machine - Mycro W-D

Sand Blasting Machine - Dryblast 600-EV1

They are used for a variety of metals for cleaning (mechanical pickling), finishing, peening, decorative sandblasting, debarring, hardening and are offered in various shapes and size depending on customer’s needs.

Micro sandblasting or shot blasting and depression process with micro-balls is considered as the best practical and cheap system prepare the surface for further coating/covering process.

Centrifugal Tumbler

Roll Fast

These are used mainly for comprehensive finish treatments

– Roughing, Grinding and Polishing of very small objects. These machines incorporate the spin speed of a main course with four containers which rotate around their axis, but in the opposite direction of the main course. This combination of movements, combined with the particular shape of the inner containers made of polyurethane [anti-wear and anti-aging] and the new “Swing System”, provides a fine finish.

Centrifugal Tumbler

Roll Fast

These are used mainly for comprehensive finish treatments

– Roughing, Grinding and Polishing of very small objects. These machines incorporate the spin speed of a main course with four containers which rotate around their axis, but in the opposite direction of the main course. This combination of movements, combined with the particular shape of the inner containers made of polyurethane [anti-wear and anti-aging] and the new “Swing System”, provides a fine finish.

Polishing Bench

Single or double place bench with suction system for dust recovery. Main technical features :

- Strong metallic structure

- Work surface in wood, lined with laminated placstic

- Protection hood with recessed lamp and plexiglass panel

- Large sucked air volume

- Filters of suitable sizes (bag filters) fixed with a quick-release system

- Emergency system for stop motor

Rolling Mill

Rolling mill is used for finishing gold and silver plates. Roll cage Oversized will bear more the maximum load. Rollers are cooled by a water circulation system.

Rolls spacing a special transmission joint transmits full power to the rolls even when opened to 45mm.

Roll parallelism can be assured by two methods:

- Micrometer setting

- Quick release gear. By means of a strong

remarkable shifting controlled by the gear with quick release.

Automatic

Manual

- Mini Rolling Mill

- Rolling Mills Hand Operated

- Rolling Mills Single Head

- Mini Rolling Mill Double Head

- Rolling Mills Combined Double Head With Gear Box & Electric

- Rolling Mill Single / Double Head Compact

- Rolling Mill Double Head (With Safety Grill & Cover)

- Strip Rolling Mill

Rhodium Gel for Color Plating

Gel Gold Plating Pen A unique effective

- OD-GP 24k Gold ingot colour

- OD-GP 24KHD 24K Yellow colour for Electonic Application

- OD-GP 1N 14K pale Yellow colour

- OD-GP 2N 18K pale Yellow colour

- OD-GP 3N 18K pinkish Yellow colour

- OD-GP 4N Pink rose colour

- OD-GP 5N Red rose colour

Rhodium Gel for Color Plating

Ready to use gel formate in 10ml,20ml,50ml,100ml

This system is a special morphology of the electrolyte, a gal form. it gives great advantages in comparison to the classical “brush/pen” plating. However it required more distinctive attentions. Advantages:

- Low investment

- Save Up to50% consumption due to thixotropic effect

- Higher resistance to oxidation

- Available in precise wide range of standard gold colors

Rhodium Gel

Rhodium Solution

* We also provide Rhodium gel and solution for white, black and copper color.

Electroplating Solution

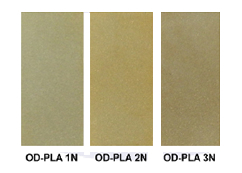

OD-PLA

Starting from weak acid electroplating processes using transition metals as brightness gold electro-deposition, working also with organic additives is born the OD-PLA series for electronic and decorative fields. These processes give smooth and glossy films at 22-24 karat, with high hardness corrosion and wear resistance moreover giving the following advantages:

- Work in relative low gold content of the baths

- Ideal for protection purposes of low karats items including silver and imitation jewelry

- High range of permissible current density

- Excellent thickness distribution and throwing power

- Low specific gravity of the gold deposits

- Easy to manage and control the processes

- Can deposit 1 or 4 microns

The new concepts of OD-PLA process is especially designed for decorative field (bijouterie, watch, spectacle frames, silverware and jewelry) in the gold plating sector. This product is versatile and available in various colours, like classical N standard series.

- OD-PLA 1N 14 gold plating baths for thick with 2 gram of gold/liter

- OD-PLA 2N gold plating baths for thick with 4 gram of gold/liter

- OD-PLA 2N 18 gold plating baths for thick with 4 gram of gold/liter

- OD-PLA 3N gold plating baths for thick with 4 gram of gold/liter

OD-FLA

This alkaline classical electroplating process, a mixture of inorganic and organic chemical additives, can be applied in the decorative fields. It comes in Powder or ready to use solution formats.

This kind of bath gives a glossy film at 22-24 karat, thanks its initials form as mixture. The new concept of OD-FLA process in decorative field (bijouterie. watch, spectacle frames, silverware, etc…) as gold plating process is “mix n’match” witch means. versatility, quick preparation operation and wide range of colours. This includes classical NI HS 03-05 Swiss standards and many others custom version, from pale gold to Old English yellow

Characteristics and advantages

- Easy to ship and bandle

- Extremely simple to set up the baths, even with basic equipment

- Excellent constancy of deposited colours thanks to high throwing power

- Wide range of gold colours

- Easy to manage and control the processes

- Designed for flash plating purposes with deposition of less than 0.2 microns

- Low gold and cyanide content

This product is versatile and available in various colours:

- OD-PLA AU 1N Ready to use flash bath with 0.6 gram of gold/liter

- OD-PLA AU 2N Ready to use flash bath with 0.7 gram of gold/liter

- OD-PLA AU 3N Ready to use flash bath with 0.7 gram of gold/liter

- OD-PLA AU 4N Ready to use flash bath with 0.6 gram of gold/liter

- OD-PLA AU 5N Ready to use flash bath with 0.7 gram of gold/liter

- OD-PLA AU 24k Ready to use flash bath with 0.7 gram of gold/liter